NASA | MYOWEAR

2015 / Pratt Institute

Wearable muscle health monitor designed for astronauts.

Created in collaboration with Larissa Naegele and Eesha Ambike.

Astronauts perform a space walk on the International Space station. Photo Credit: NASA

NASA's Wearable Electronics Application and Research (WEAR) Lab challenged students to attach technology to the body of an astronaut without building it into a custom garment. Our team responded by marrying technology targeting health and fitness with a form fitting attachment method.

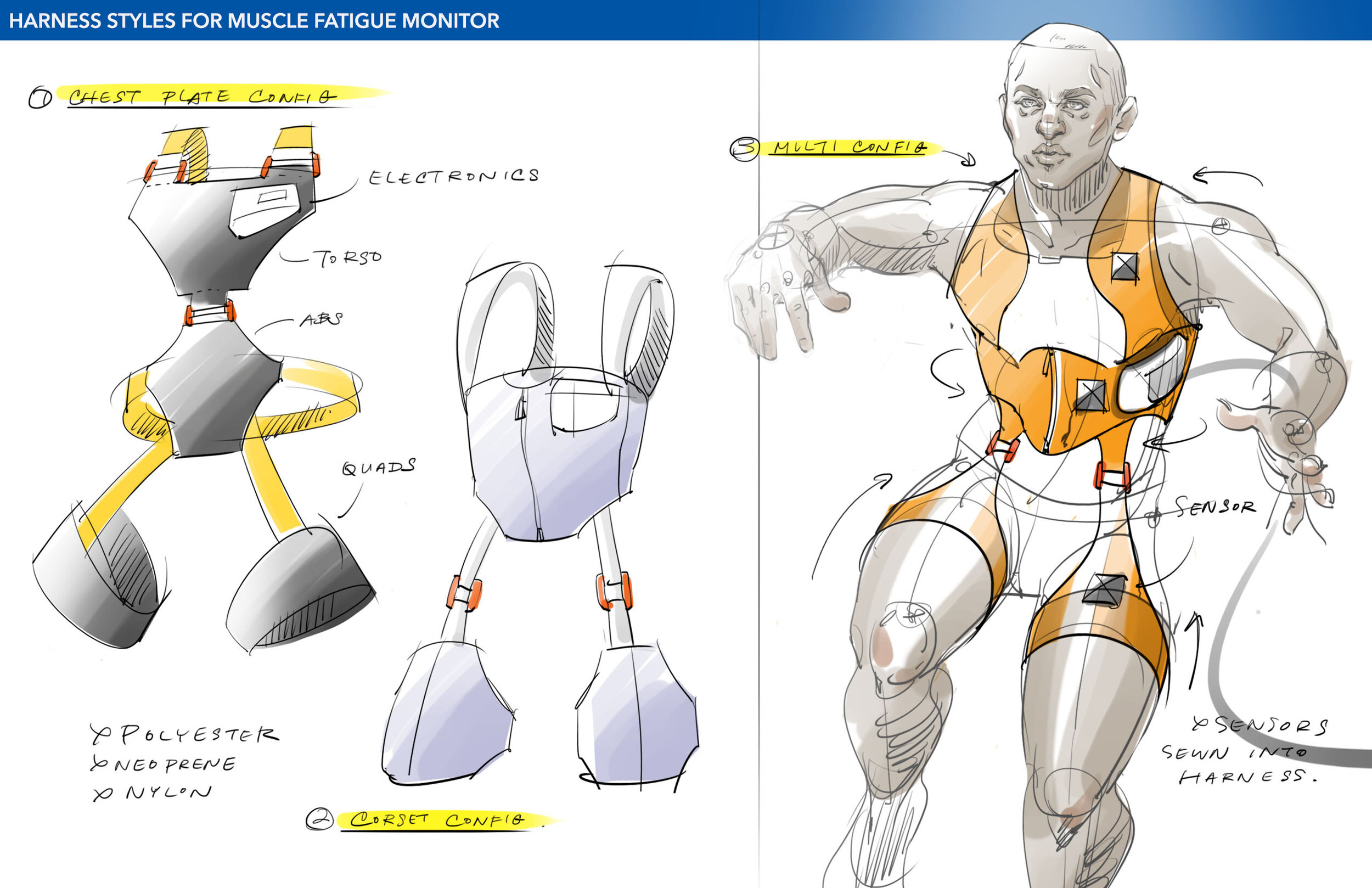

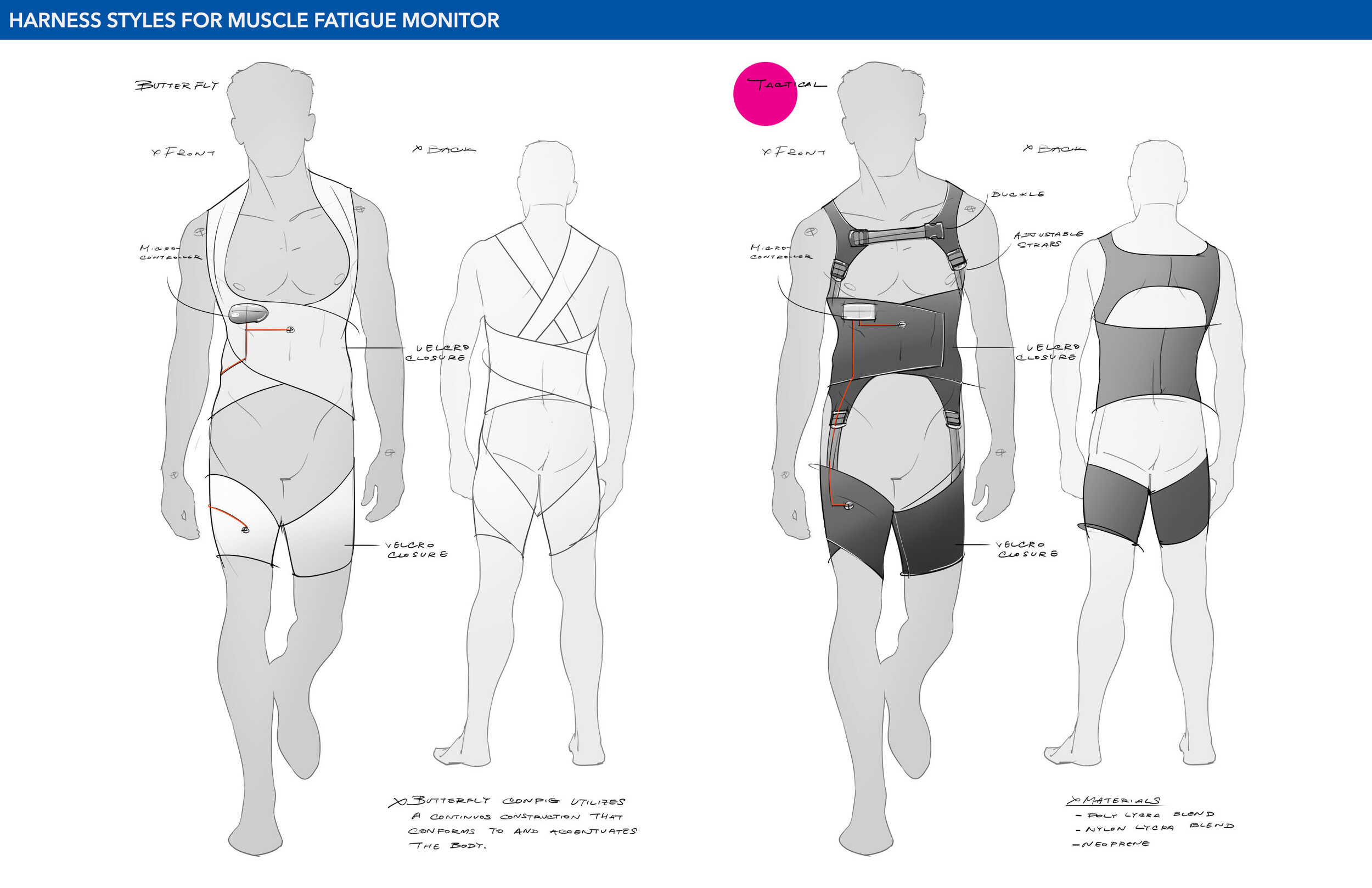

MYOWEAR monitors muscle contractions during exercise, improving data collection by providing real time biometric feedback for the user. The form fitting full body harness secures sensors to the body and has the potential to carry other pieces of equipment.

THE BODY IN SPACE

In a free fall gravity environment, the body adapts to the lack of gravitational pull by eliminating muscle tissue. Muscle mass decreases at a rate as high as 5% a week, most notably in the leg and back muscles that experience less load bearing. To combat muscle atrophy, astronauts are required to exercise vigorously aboard the station in order to preserve muscle mass.

Electromyography (EMG) is a contemporary technique used to monitor muscle health. Adhering several surface EMG electrodes to large muscle groups detect electrical signals as the muscles contract. The Myomonitor, developed by Delsys Inc., for example, is an electrode to skin interface that's been evaluated by NASA to study the muscles of astronauts in free fall gravity.

Observing the Myomonitor’s tangle of wires and electrodes, my team sought to streamline an attachment method that would allow astronauts to monitor their muscle health during exercise without any obstruction.

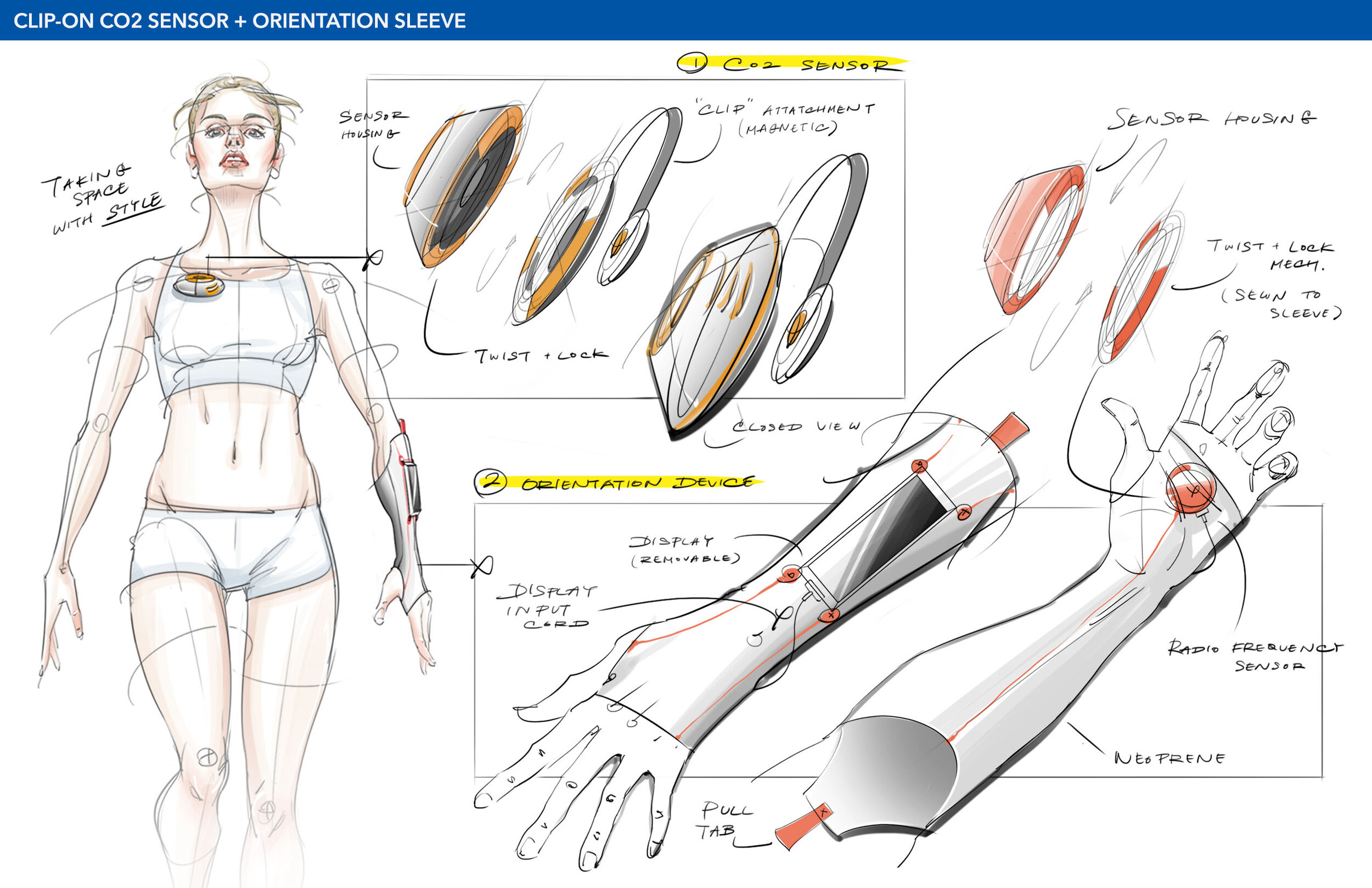

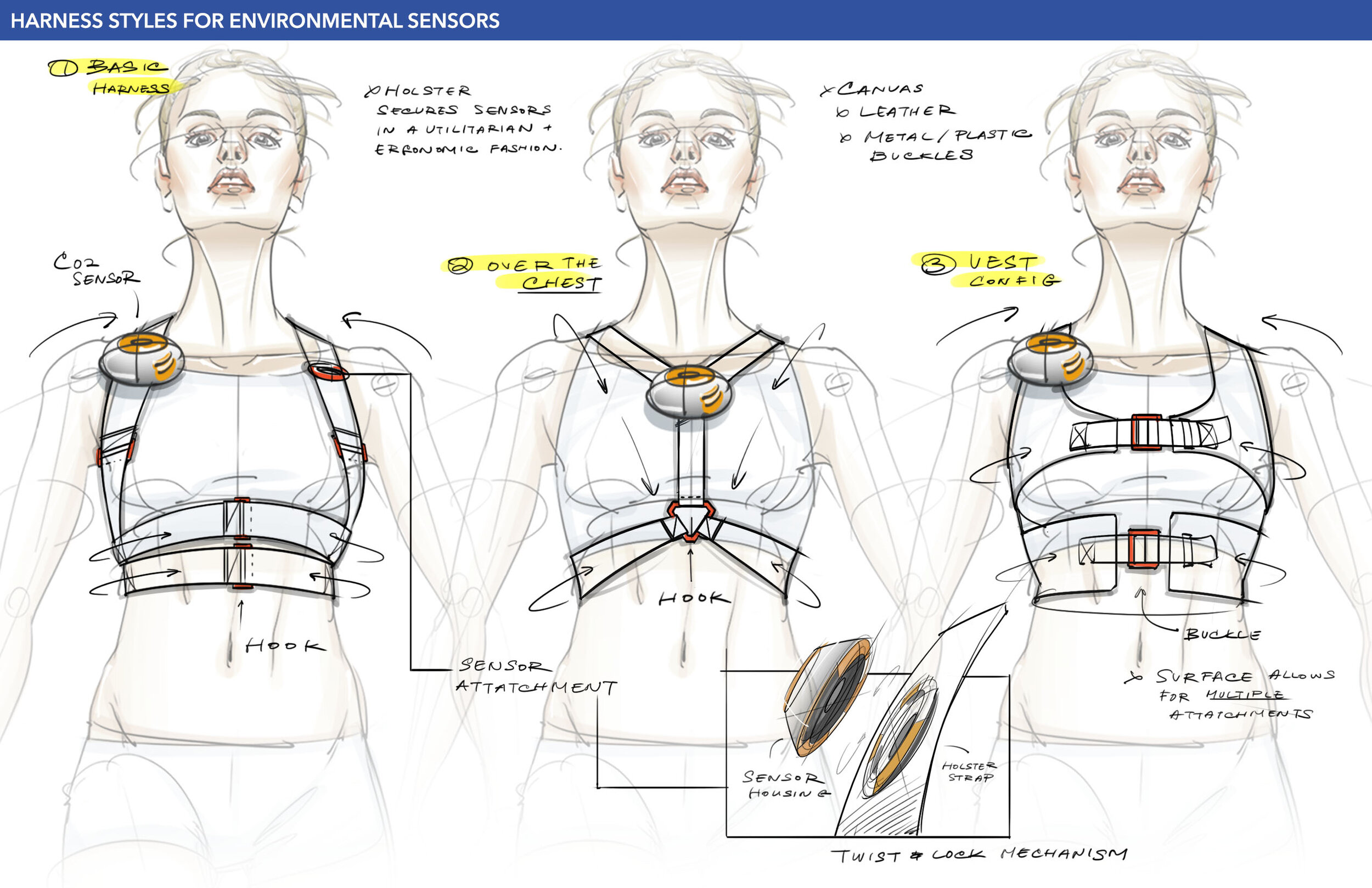

Initial concepts explore environmental and orientation sensors before a full body harness is developed for the purpose of monitoring muscle fatigue.

ACOUSTIC MYOGRAPHY

Our engineer, Eesha, proposed the use of an acoustic sensor to test for muscle fatigue. Acoustic myography records the low frequency sounds generated by the muscles during contraction. This sound is observed to be between 10-50 Hz, with a peak around 25 Hz. The amplitude of this signal decreases as stress in a particular muscle increases. This phenomenon can be used to monitor muscle health without having to dip into the cost of electromyography.

A low frequency acoustic sensor will be incorporated into the harness and placed in direct contact against the skin. Muscle contractions during exercise or daily motions will be recorded on a data acquisition system. The advantage of acoustic myography lies in its non-invasive technique that is easy to use and operate for the purpose of proving our design concept.

Two large muscle groups, the pectorals and quadriceps, have been targeted for monitoring.

Exploded diagram on the right illustrates how the acoustic sensor interfaces with the harness and skin surface. Keeping the wiring concealed and flexible to the stretch of spandex was essential in making this piece of technology wearable.

WHAT’S INSIDE

MYOWEAR was exhibited at:

Johnson Space Center | Houston, TX

Wearable Technology Symposium (May 2015)

Brooklyn Fashion + Design Accelerator | Brooklyn, NY

Cloud Couture: The Intimate Connection Between Fashion and Technology (Feb 2015)

Beit Ha'ir Museum | Tel Aviv, Israel

My Shirt is Breathing: Intelligent Wearables - Fashion and Technology (Mar 2015)